WHAT IS A CBV

The CBV (Concrete Batching Vehicle) is a technology that transform a traditional Self Loading Mixer into an off-road vehicle that operates as a true mobile batching plant, allowing the production of certified concrete in any setting, anywhere. Thanks to the electronic PROCESS CONTROL, this innovative concept makes possible to certify the quality of the concrete and assure that the operator will produce uniform batches of concrete over and over, according to the requested recipes and workability. It is a “portable” solutions which doesn’t require the use other resources (people or vehicles) to get certified concrete.

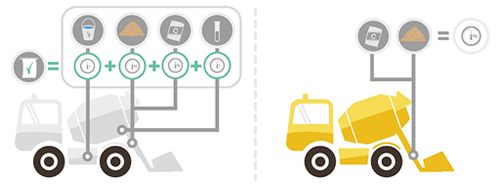

WHY THE CBV ISN’T AN ORDINARY SLM

The technology and electronics implemented in the CBV vehicles provides an integrated system that leads the operator to reduce human errors: the operator will be able to program and store up to 20 concrete mix recipes, mass measuring the components, control the mixing time, diagnose the end of the mixing process, compensate the moisture content in the aggregates, and include up to nr. 2 admixtures. The traditional Weighing System of SLM’s, is only a “scale” that helps size batches of concrete, therefore it gives the misleading idea of controlling the quality of the concrete.

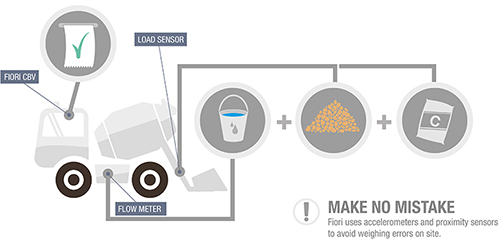

HOW THE CBV WORKS

- it measures by mass the different components with extreme precision;

- it allows to dump excess materials (tip-off function) ;

- it controls the mixing time, nr. of revolution and RPM of the drum;

- it diagnoses the end of the mixing process (and homogeneity of the slump) in virtue of the stabilization of the drum reductor’s pressure sensor;

- it grants the correct W/C ratio by compensating the aggregates moisture and automatically; stopping the water’s flow into the drum;

- it prints out a report of the mix produced and verifies its match to the programmed recipe;